Overhead line insulators are electrical insulation devices used to support overhead electrical line conductors on the support structures. These line insulators make sure that there is no flow of leakage current, from the line conductors to the earth, through the supports. The line insulators are attached to the projected arms of the supports and the current carrying line conductors are pinned to the insulators, in order to provide the necessary insulation and isolation between the live conductors and the metal work of the supports. The separation of the conductors with the metallic supports can be controlled by increasing the length of the conductor and increasing the length of the cross arms.

Overhead line insulators are electrical insulation devices used to support overhead electrical line conductors on the support structures. These line insulators make sure that there is no flow of leakage current, from the line conductors to the earth, through the supports. The line insulators are attached to the projected arms of the supports and the current carrying line conductors are pinned to the insulators, in order to provide the necessary insulation and isolation between the live conductors and the metal work of the supports. The separation of the conductors with the metallic supports can be controlled by increasing the length of the conductor and increasing the length of the cross arms.

The properties of a good overhead insulator are:

- The insulators should possess ruggedness and high mechanical strength; they should be able to bear the stress of the conductor weight as well as the pressure due to heavy winds and snow.

- It is highly desired from an overhead line insulator to possess high relative permittivity or dielectric strength to prevent puncture through phenomena through insulator in case of high voltage surges.

- The insulators should have high insulating properties or high resistance to prevent the flow of leakage currents to the ground though the insulators.

- The insulators should have a high ratio of puncture strength to flash over voltage.

- Another desired characteristic of a good insulator is the ability to withstand high degree of temperature variations. The insulators should not crack from exposure to repetitive climatic and temperature changes.

Types of insulating material:

Porcelain – It is produced by heating a combination of quartz, feldspar, kaolin at a controlled temperature. Porcelain is stronger than glass in terms of bare mechanical strength and also possesses better leakage strength and better resistance towards temperature variation.

Glass– It is more homogeneous and cheaper than porcelain and if reinforced and properly toughened provides better dielectric strength and higher resistivity. The most beneficial property of a glass insulator is the ease of designing and molding.

Steatite– Steatite is synthetic compound manufactured from combination of naturally occurring magnesium silicate with oxides in varying proportions. It has much larger bending strength and much higher tensile strength than porcelain, it finds major application in places where the transmission line take sharp turns and require high bending.

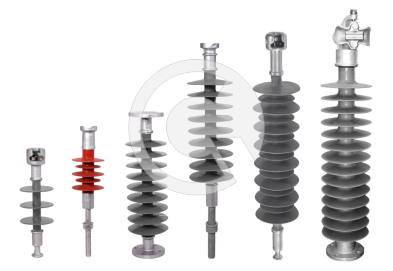

Types of insulators

- Pin Type Insulators – The most earliest and widely used insulator type of insulators used for supporting line insulators. It provides the most efficient, simple and economic method of conductor and bus bar support for voltages up to 33KV.

- Strain type insulators – These are special type of insulators that find application when the line conductors to be supported meet a dead end or a sharp corner. These insulators are designed to withstand a lot of strain and hence the name.

- Suspension type insulators – Suspension type insulators consists a number of porcelain discs combined together with the help of a metallic link. These suspension insulators hang from the arms of the supports and support the conductors. The number of discs in an insulator is proportional to the voltage carried by the lines.

- Long rod insulators – Increasingly the newer design Long rod insulators are replacing the suspension type insulators, due to their simpler construction. Unlike the pin type insulators, the long rod insulators can be manufactured as a single unit and the economies of scale can be achieved in production.