A basic decision you must make when planning ducted extraction systems is whether to use metal or flexible ducts.

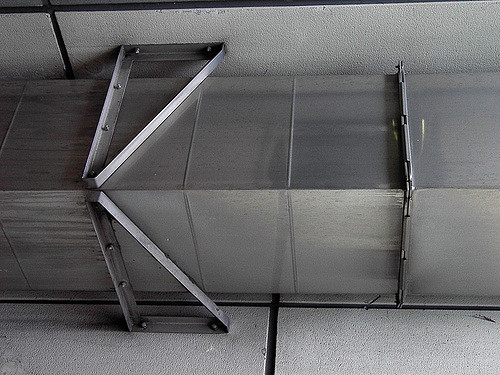

Metal ductwork

There are ways to make metal light and flexible, but in general, it is a heavy and rigid. Metal HVAC systems are made to last, which is perfect if you aren’t planning to redesign operations on a regular basis.

They are generally made of aluminium or galvanised steel. Cross-sections may be rectangular, circular or oval, and they are chosen to optimise airflow rather than for aesthetic considerations.

Transporting air through ducts may seem simple, but a large installation requires sophisticated planning to ensure it works. Professional contractors like https://www.dustspares.co.uk/flexible-ducting/ begin by computer-modelling the system to determine the relationships between profiles, inclines, angled turns and airflows. The effects introduced by system components like fans, dampers, heat exchangers and filters must all be modelled in.

When a system has been carefully modelled, using a durable material helps ensure it continues to function as designed.

Metal is easy to clean internally, and its smooth surface offers little resistance to airflow, minimising the energy costs of powering the system.

Flexible duct

Flexible ducting comes in several forms. Some are as lightweight as paper supported on a wire spiral. Most are manufactured from rubber, silicone, neoprene and polyester, or from PVC.

Ducts of flexible materials are more versatile and adaptable. They can be installed in less time and at lower costs. Conversely, it is harder to ensure a material that is adapted as it is installed will maintain the precise parameters required by the system design.

Flexible ducts, especially those with a concertina-like profile, present variable resistance to the passage of air depending on how they are stretched, twisted or inclined. They are also harder to clean, presenting fire and health and safety challenges (see http://www.modbs.co.uk/news/archivestory.php/aid/8019/Do_your_ventilation_systems__meet_legal_requirements_.html).

Installation errors, increased resistance to airflow, and heavier maintenance requirements can quickly undo capital expenditure savings through increased operating costs.

Happy compromises

Often, the ideal solution is a trunk constructed of metal, with branches to specific areas made from short runs of flex. If your plant, desk or kitchen arrangement changes, a flexible final run is quick and easy to adjust without seriously affecting the core of the system.

However, the perfect solution depends a great deal on your building, so protect your HVAC investment by hiring experienced professionals.